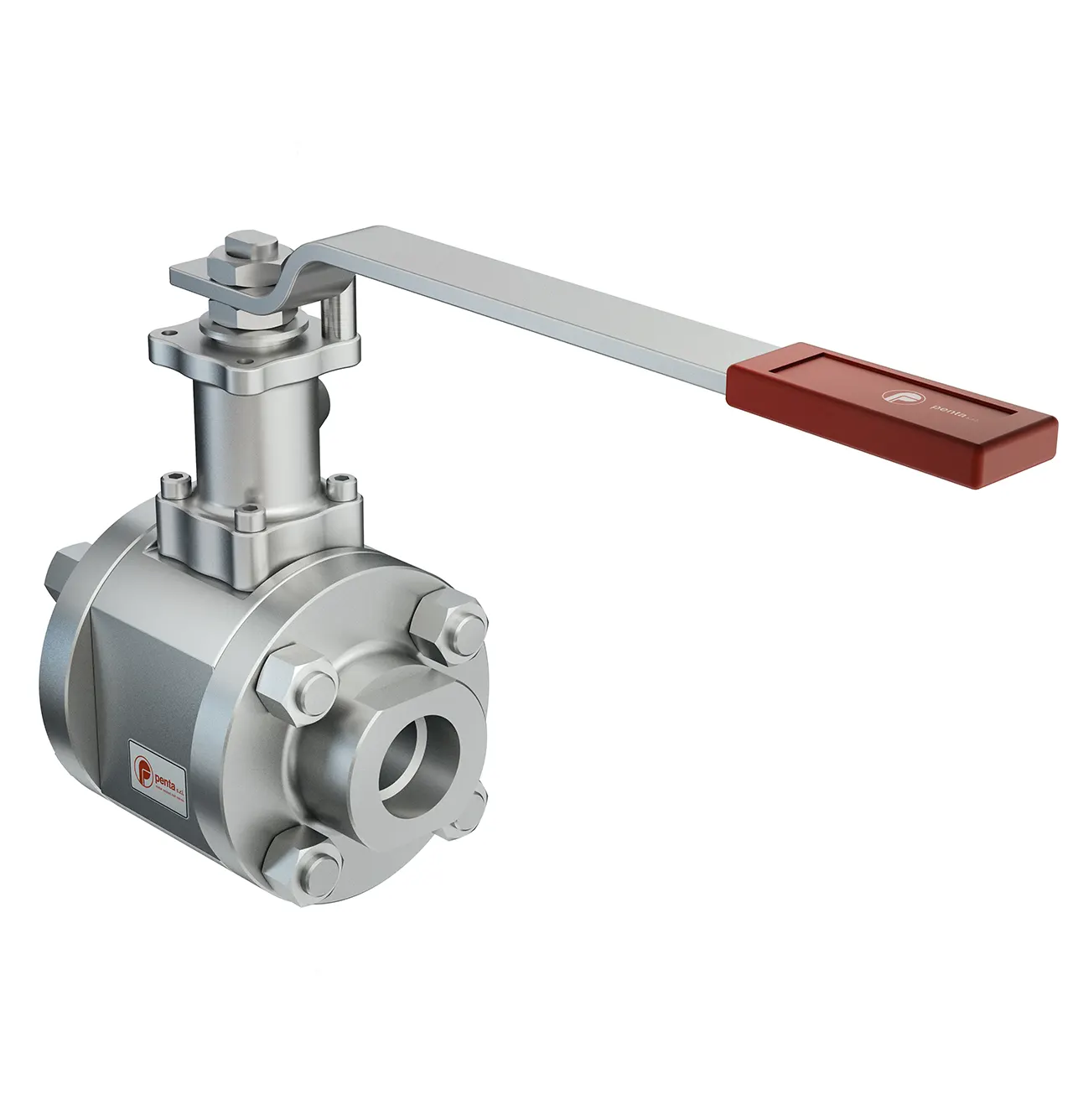

Split body ball valve for mild-high temperatures from -50°C to +400°C with soft or metal seats.

The AP ball valves are designed to be used in a wide range of applications and for temperatures from -50°C to +400°C.

The AP series provides some design solutions adopted for the most performing models of our production, such as SAT and 3W series, that today are still unique on the market: the self-lubricated metal seats in PENTAFITE, pre-loaded with springs, the special expanded graphite seals and the “live loaded” stems.

Technical features

|

DESIGN

|

Floating and trunnion ball, full or reduce bore, split body

|

|

DIMENTION RANGE

|

DN 1/2” – DN 10” |

|

PRESSURE CLASSES

|

ANSI 150-1500 PN 16-250 |

|

TEMPERATURE RANGE

|

-50°C / +400°C |

| DESIGN STANDARD | ASME B16.34 / EN 12569 / EN 17292 / ASME VIII DIV.1 / EN 12516-1 |

| FACE TO FACE | ASME B16.10 / EN 558 |

|

CONNECTIONS

|

ASME B16.5 / EN 1092-1 / DIN / GOST 54432 / GOST 12815 |

|

BODY MATERIAL

|

A105 / A350 LF2 / AISI 316 / AISI 304 / other materials on request |

| SEATS | PENTAFITE / WC / CRC / ST6 / RPTFE (only ANSI 150/300 Floating) |

| STEM DESIGN | ANTI BLOW-OUT |

| MOUNTING | ISO 5211 |

|

TIGHNESS CLASS

|

ASME B16.104 / FCI 70-2 Cl. VI / API 598 Cl. A / GOST 54808 Cl. A |

EC Directive 2014/34/UE “ATEX”

FIRE SAFE API 607 ISO 10497

TA-LUFT Approved (only if equipped with stem elongation)

FUGITIVE EMMISSION ISO 15848-1 (onyl if equipe with stem elongation)

SIL3 IEC61508

EAC Approval

CRN Approval

The double ring system with loading nuts allows the correct stem gasket pre-loading and the adjustment to recuperate wearing and clearance for different thermal dilation between stem an body

GASKETS

Only Grafoil® gaskets are used, inherently resistant to high temperatures: no polymers are used

STEM

Stems are 100% oversized against expected torque at max. rating DP.

BOLTING AND FLANGES

All flanges connections are designed according to ASME VIII Div.1 and ANSI B16.34.

BALL

Very high precision grounded balls are produced inside and then they are hard coated with most advanced systems

SEATS

Metallic seats are pre-loading with springs for a perfect low pressure bubble tightness and to recuperate life wearing and different thermal dilatation between internals.

Over the years Penta has managed to maintain these product qualities even making the AP model available on a larger scale through the mass production of some components, such as the metal seats in Pentafite, which make the AP model ball valves the most competitive on the market.

The use of metal seats in PENTAFITE allows the creation of ball valves with metal seats with ZERO LEAKAGE, easy to maintain, without the need of adaptation between seats and balls and with 40% reduced operating torques compared to standard metal seats solutions.

The same attention is paid to verifying the degree of tightness towards the outside through the TUV certification of compliance with the limits imposed by the German TA-LUFT regulation and ISO 15848-1 certification.

AP11: Wafer ball valve with floating ball, completed detachable for maintenance, with integral heating jacket.

AP60 / AP64 / AP606 / AP609 / AP68 / AP50 / AP54 / AP506: Split Body ball valve with floating ball, completed detachable (for the replacement of seats and gaskets).

APT2: Split Body ball valve with trunnion ball, completed detachable (for the replacement of seats and gaskets).

| INTERVALLO DI PRODUZIONE | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ancora in fase di modifica | |||||||||||

| ANSI B 16.34 | 150 | 300 | 600 | 900 | 1500 | ||||||

| PN | 16-25 | 40-50 | 64-100 | 160 | 250 | ||||||

| F | T | F | T | F | T | F | T | F | T | ||

| Diametri Nominali | Modelli | AP54 AP64 AP68 AP10N AP11N |

APT2 | AP50 AP60 AP10N AP11N |

APT2 | AP506 AP606 AP10HP |

APT2 | AP609 | APT2 | AP615 | APT2 |

| ½” | |||||||||||

| ¾” | |||||||||||

| 1” | |||||||||||

| 1¼” | |||||||||||

| 1½” | |||||||||||

| 2” | |||||||||||

| 2½” | |||||||||||

| 3” | |||||||||||

| 4” | |||||||||||

| 6” | |||||||||||

| 8” RB | |||||||||||