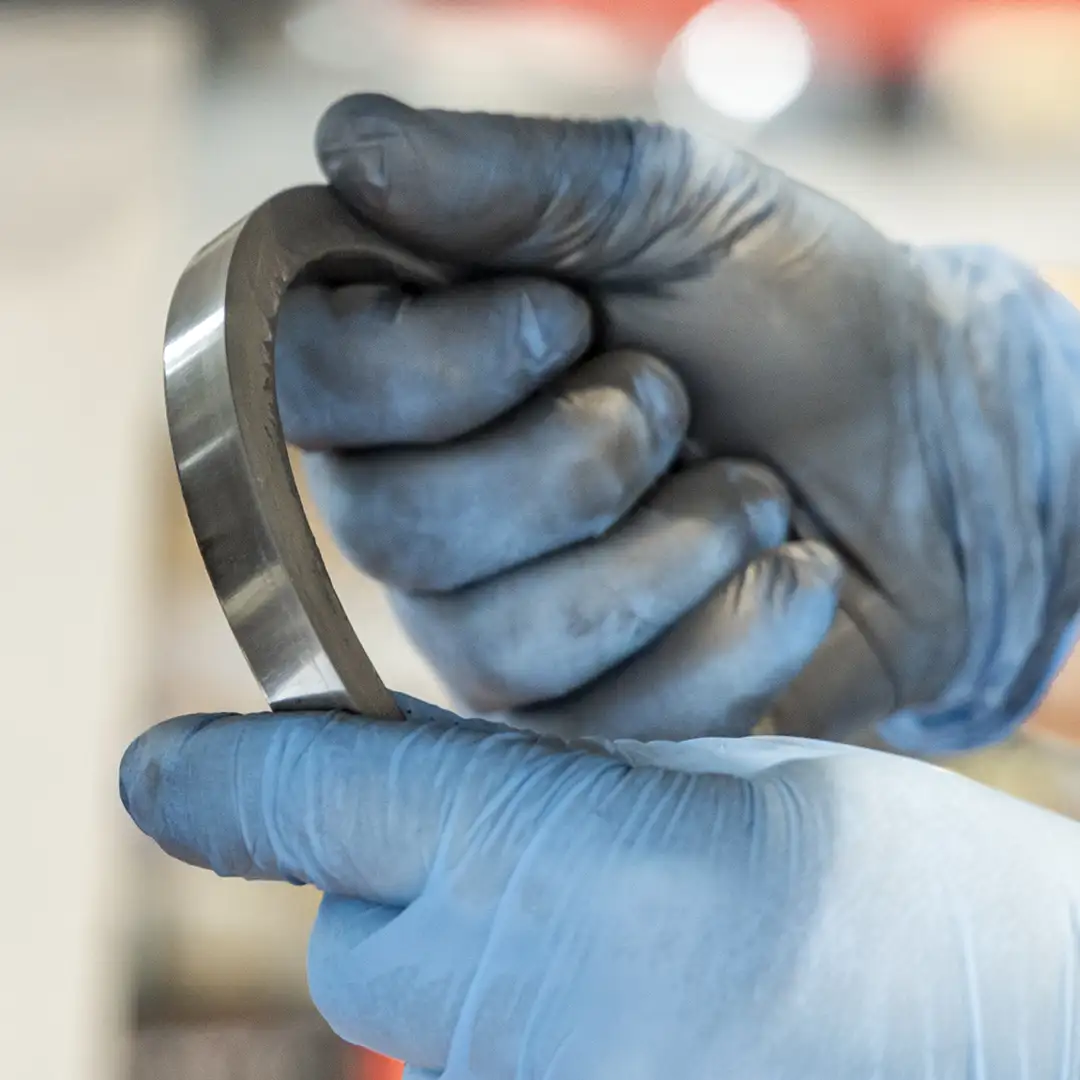

PENTAFITE is a compound with metallic matrix and fine dispersion of solid lubricant inside used for the production of the unique Penta patented metallic seats.

It is obtained by a manufacturing process similar to sintering with which, starting from fine powders of the single component, is possible to produce the metallic rings that form the seat insert for our metal seated ball valves for services with high temperature, high pressure or with combination pressure/temperature higher than tolerable limits for polymeric material.

Main features of Pentafite Metal Seats

1 PERFECT TIGHTNESS

Superior Elastic properties of PENTAFITE seat material allow the automatic adaptation of seats against ball shape, eliminating machining imperfections. This way it is possible to eliminate any possible leak-point and to meet the perfect tightness.

2 LOW VALVE TORQUE

The presence of the solid lubricant dispersion inside the metallic matrix, allows a 40% reduction of seat to ball friction factor as like as valve torque. For the same reason seizure or galling between seat and ball surfaces are eliminated even when the working temperature is high.

3 EASY MAINTENANCE

Valve assembly and maintenance are very easy when PENTAFITE metal seats are used because it is not necessary any additional machining to adapt seats against the ball (You do not have to lap the seat against the ball).

4 GAS TIGHTNESS

The presence of the solid lubricant inside allows the PENTAFITE material to reach very high working specific pressures resulting in perfect tightness when high pressure gases must be stopped.