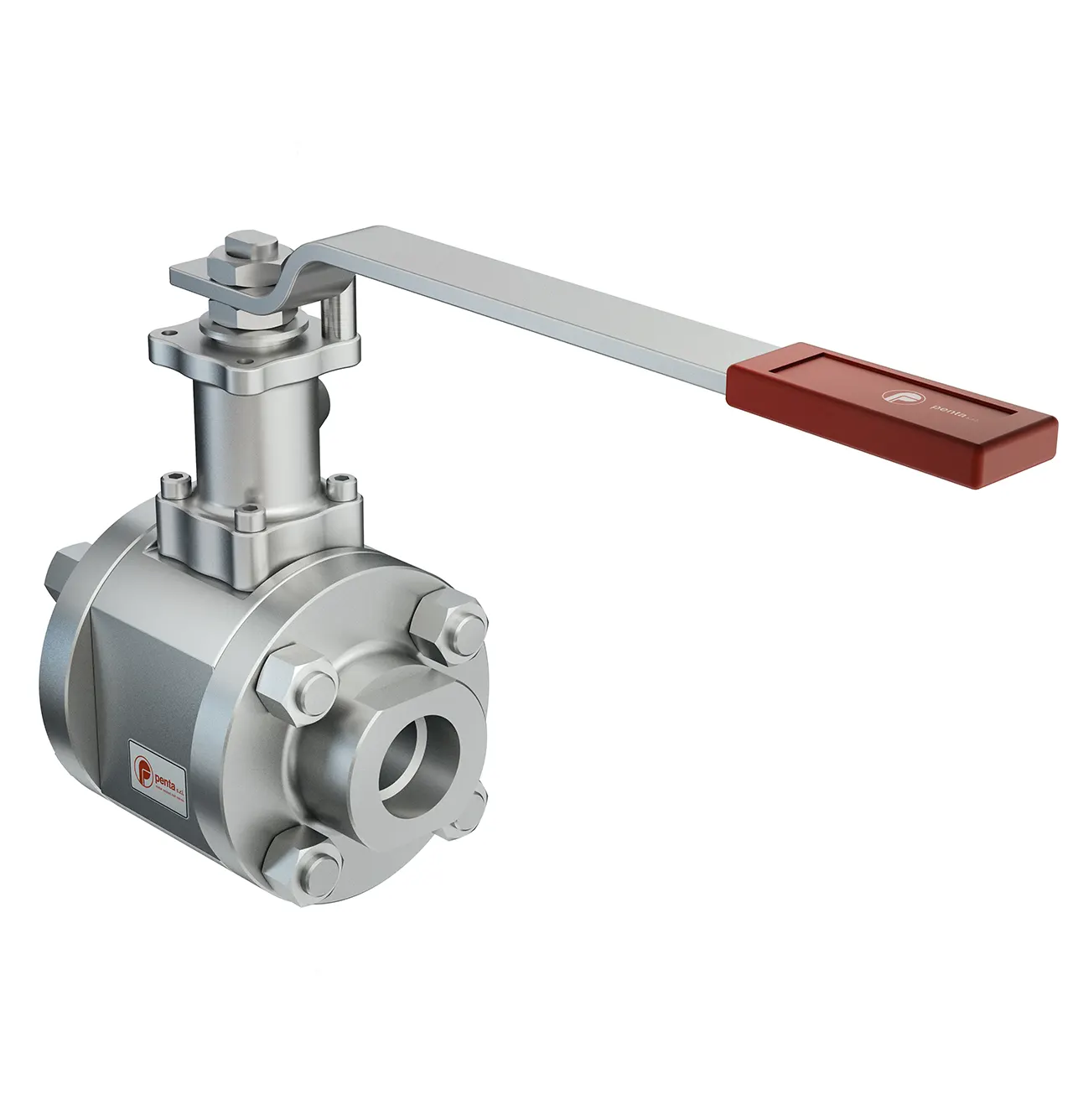

Metal seated ball valve for high temperature from -100°C up to +720°C

The SAT model is the PENTA valve construction that best suits a wide range of uses.

The first aim of the design philosophy is to achieve maximum reliability, through the implementation of technical solutions that still today are unique on the market.

Technical features

| CONSTRUCTION | Floating or Trunnion Ball, Full or reduce Bore, Split Body |

| DIMENTION RANGE | DN 1/2” – DN 18” |

| PRESSURE CLASSES | ANSI 150-2500 PN 16-420 |

| TEMPERATURE RANGE | – 100°C / +720°C |

| DESIGN STANDARD | ANSI B16.34 / API 608 / API 6D / ISO 14313 / EN12569 / EN17292 / ASME VIII Div.1 / EN 12516-1 |

| FACE TO FACE | ASME B16.10 / EN 558 |

| CONNECTIONS | ASME B16.5 / EN 1092-1 / DIN / GOST 54432 / GOST 12815 |

| BODY MATERIAL | A105 / A350 LF2 / AISI 316 / AISI 304 / other materials on request |

| SEATS | PENTAFITE / WC / CRC / ST6 / PEEk (fino DN 6″) |

| STEM DESIGN | ANTI BLOW-OUT |

| MOUNTING | ISO 5211 |

| TIGHNESS CLASS | ASME B16.104 / FCI 70-2 Cl. VI / API 598 Cl. A / GOST 54808 Cl. A / EN 12266-1 / ISO 5208 |

EC Directive 2014/68/UE “PED”

EC Directive 2014/34/UE “ATEX”

FIRE SAFE API 607 ISO 10497

TA-LUFT

SIL3 IEC61508

Approvate EAC

Approvate CRN

Unique stem seal design realized in Penta. The spring placed at the stem top gives the contact load for low pressure tightness and the adjustment for wearing and clearance for different dilatation between stem and cover.

GASKETS

Only Grafoil® gaskets are used, inherently resistant to high temperatures.

STEM

Stems are 100% oversized against expected torque at max. rating DP.

BOLTING AND FLANGES

All flanges connections are designed according to ASME VIII Div.1 and ANSI B16.34.

BALL

Very high precision grounded balls are produced inside and then they are hard coated with most advanced systems.

SEATS

Metallic seats are pre-loading with springs for a perfect low pressure bubble tightness and to recuperate life wearing and different thermal dilatation between internals.

UPPER COVER

All SAT/APT3 valves are provided with bolted upper cover for quick and easy stem assembly maintenance.

The typical elastic properties of Pentafite seats and the sully bolted construction allow an easy maintenance without necessary of additional lapping of the seats against the ball.

Hard coated seats are also available.

SAT valves are available with Floating or Trunnion mounted ball, with reduced or full bore and all valves are provided with automatic body cavity pressure relief arrangement.

SAT TRU: 2 or 3-piece Split Body valve with Trunnion ball

APT3: 3-piece Split Body valve with Trunnion ball

| INTERVALLO DI PRODUZIONE | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ancora in fase di modifica | |||||||||||||

| ANSI B 16.34 | 150 | 300 | 600 | 900 | 1500 | 2500 | |||||||

| PN | 16-25 | 40-50 | 64-100 | 160 | 250 | 420 | |||||||

| F | T | F | T | F | T | F | T | F | T | F | T | ||

| Diametri Nominali | Modelli | SAT FLOTT | SAT TRUN APT3 | SAT FLOTT | SAT TRUN APT3 | SAT FLOTT | SAT TRUN APT3 | SAT FLOTT | SAT TRUN | SAT FLOTT | SAT TRUN | SAT FLOTT | SAT TRUN |

| ½” | |||||||||||||

| ¾” | |||||||||||||

| 1” | |||||||||||||

| 1¼” | |||||||||||||

| 1½” | |||||||||||||

| 2” | |||||||||||||

| 2½” | |||||||||||||

| 3” | |||||||||||||

| 4” | RB | ||||||||||||

| 6” | |||||||||||||

| 8” | RB | RB | |||||||||||

| 10” | |||||||||||||

| 12” | |||||||||||||

| 14” | |||||||||||||

| 16” | |||||||||||||

| 18” | |||||||||||||