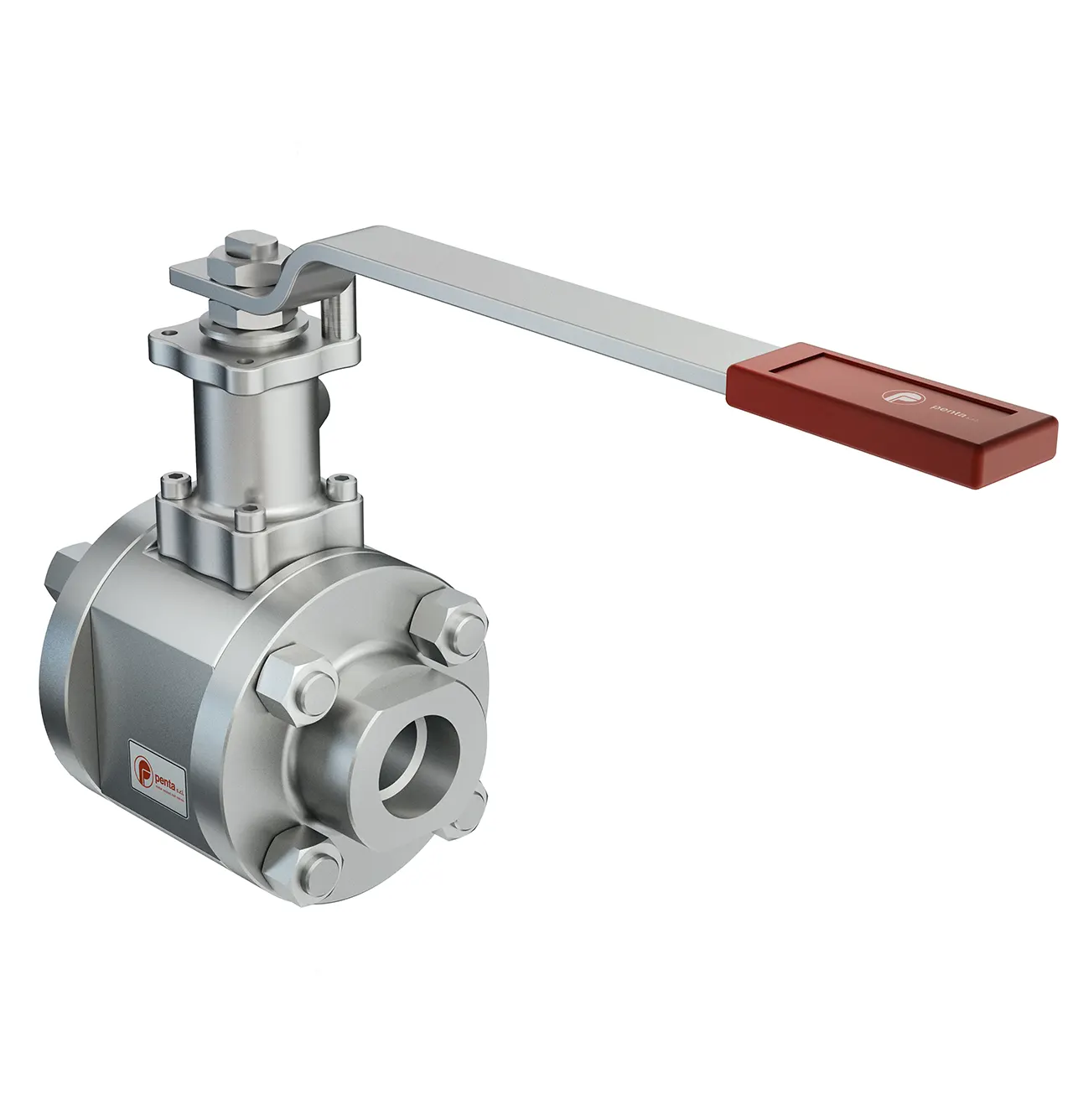

Wide range of ball valves

We cooperate to identify the best model and construction suiteable for the real operating conditions.

EXPERIENCE AND PASSION

The longstanding experience in the production of ball valves for industrial plants, the constant innovation in Research and Development to meet the needs of all our customers and sector, combined with the availability of unique solutions in the market, make Penta a competent and reliable supplier in the field of industrial ball valves.

Using a wide range of innovative and high quality materials, Penta is able to find the most suitable solution to meet customer need.

All Penta ball valves can be customized and adapted to meet the real purpose of use.